FUSION: MARKET INTELLIGENCE

Taiwan Manufacturers Overcome Drought Challenges | Fusion Worldwide

The island of Taiwan is experiencing its worst drought in over 50 years. For the entire semiconductor industry, this could mean exponentially worsening shortages.

While only 20% of Taiwan's water supply goes toward industrial production, water is essential in processing silicon and for other aspects of chip manufacturing. To combat the issue, TSMC has ordered truckloads of water to be delivered to certain facilities to maintain production, as well as implementing water-saving practices.

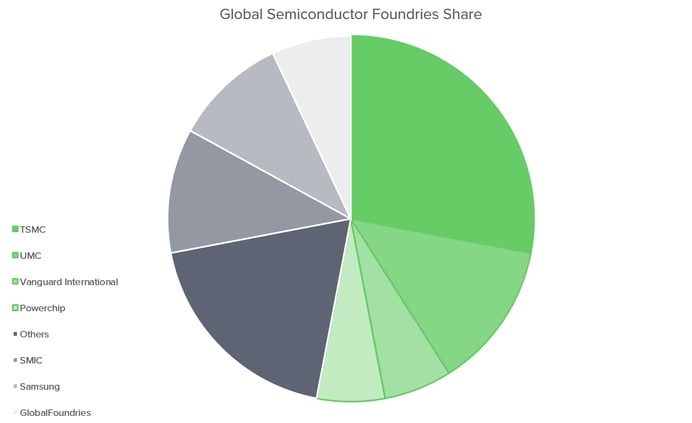

Taiwanese plants and foundries produce roughly 53% of the global semiconductor market, down from 66% in 2017. With four of the ten global semiconductor foundries having facilities in Taiwan, the possibility of water shortages through June 2021 could be a major blow to semiconductor production.

Taiwan-based factories are identified in green.

In Jan. 2021, TSMC announced efforts to reallocate wafer capacity for automotive applications to support the industry struggling to make a comeback after 2020. Automotive plants around the world are at a standstill due to chip shortages. In spite of reallocation efforts, supply is still struggling to meet the increased demand, and curbing production due to water shortages could further delay the recovery of the automotive sector.

TSMC's reallocation away from other applications and industries is increasing the semiconductor market volatility. Raw material shortages, plant fires and power outages, are just a few of the unforeseen events that have disrupted manufacturers from resuming normal operations. Along with the ongoing drought, Taiwan is also experiencing another wave of COVID-19 and geopolitical tension.

Frequently Asked Questions

How is the drought in Taiwan affecting semiconductor manufacturing?

The drought, the worst in over 50 years, poses a risk because water is essential for processing silicon and chip manufacturing. Companies like TSMC are implementing water-saving practices and ordering truckloads of water to maintain production levels.

What percentage of the global semiconductor market is produced in Taiwan?

Taiwanese plants and foundries produce roughly 53% of the global semiconductor market. Furthermore, four of the ten global semiconductor foundries have facilities located in Taiwan.

How has TSMC responded to shortages in the automotive sector?

In January 2021, TSMC announced it would reallocate wafer capacity to support automotive applications. Despite these efforts, the supply is still struggling to meet increased demand amidst production challenges.

Aside from the drought, what other factors are disrupting the semiconductor supply chain?

Manufacturers are facing raw material shortages, plant fires, power outages, and geopolitical tensions. Additionally, Taiwan is experiencing a wave of COVID-19 cases that further complicates operations.

What services does Fusion Worldwide offer?

Fusion Worldwide is an open market distributor that sources, inspects, tests, and delivers a broad range of electronic components. They serve a diverse customer base, including OEMs, CMs, and ODMs.

What is Prosemi's role within the Fusion Worldwide network?

Prosemi is a subsidiary of Fusion Worldwide located in Singapore. It operates as an extensive testing and assembly house, providing comprehensive electronic component quality testing solutions.